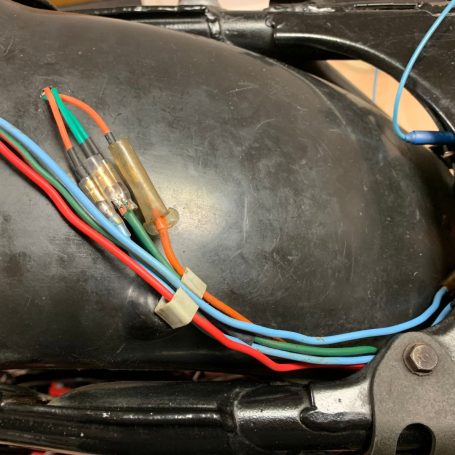

Another fabulous day where we got stuck into the wiring. The challenge on the cafe racer, typical with a lot of older bikes, is the wiring colours were not all as per the wiring diagram as over the years extensions and alterations were done in a, shall we say, "will do" fashion making it a bit of a detective novel but the basic principles remain the same so wasn't too bad. We were pleased with the bike when we got to the battery connection stage and found no hidden short circuits so everything worked as we had anticipated, one missed area but should be easy to resolve, happy days. Happy to report the indicators, brake lights and parking lights all work now, always nice to see the bike "waking up" like this after a long time in limbo.

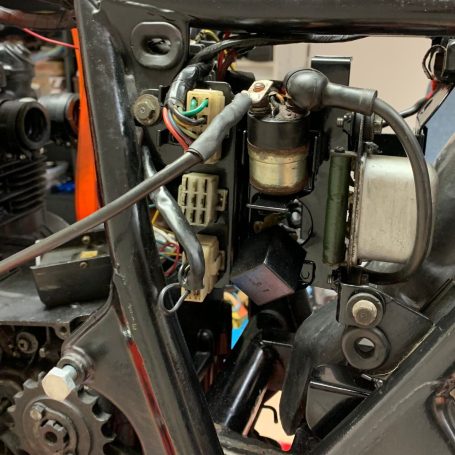

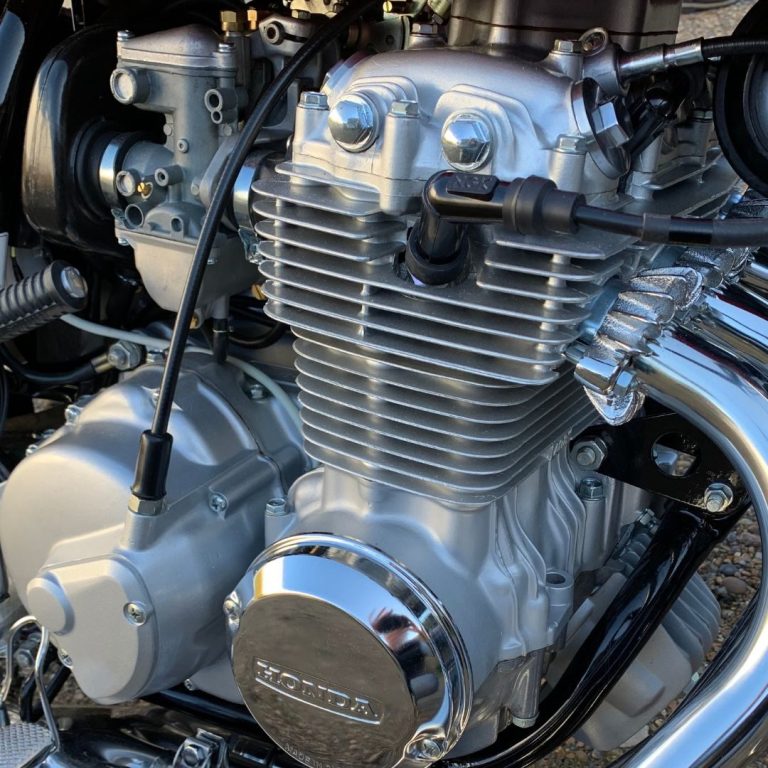

A polishing job we had sent away some time ago comes back and we are delighted with it, talking to the painters there is a product called Ceracote but the spray applied version not the ceramic one that we can add over them that will keep them, 95% anyway, as good as new without hours of elbow grease! This is an option I think we will take as we have so many bikes we simply cannot keep them all perfect all the time and any time saving devise we welcome!.

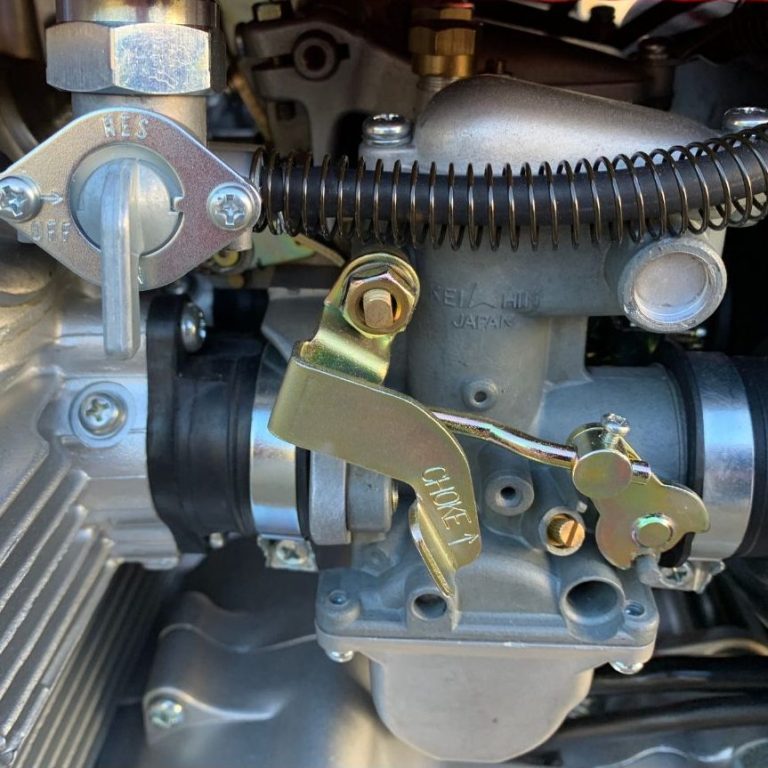

We had sourced a carburettor renovation kit on Ebay which was not OEM and paid the price as the parts were incorrect, that will teach us to penny pinch, be warned!

We suffer a moment of madness as we got a set of beautiful professionally refurbished carbs out of the stores but sense hit us just in time and we held back, they are so good they should go onto a concours build not the cafe racer, she does not command that level of detail. We will await a suitable refurbishment kit and come back to the job at a later date.

Great times as the bike keeps on making us smile, maybe a bit less than normal but that's electrics for you :)

Danny the polishing wizard waves his magic wand, believe it, gorgeous!

There polished Jim but not as we know it :)

CB400/4 F2 project

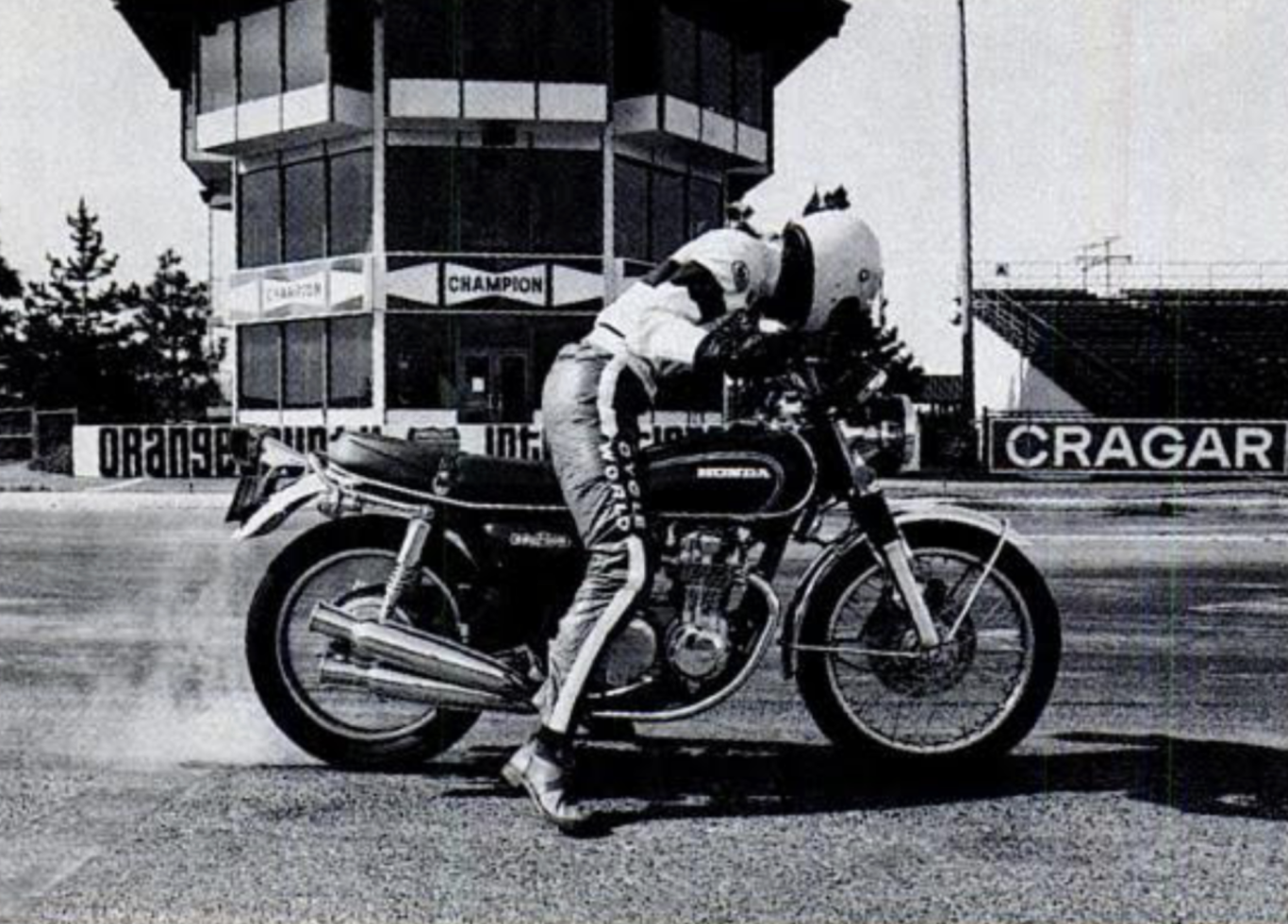

£4000! Are you having a laugh?

We love an old Honda as much as the next man and one we can get to grips with bringing it back to its former glory all the better but what are people thinking when they offer us old bikes at such, for us anyway, massively inflated rates?

This bike would come back to a really good example if not massively collectable to be fair when fitted with the 550 engine although I do think the 550 power plant is a better unit having a six speed box and works well on todays faster roads but it definitely detracts for the collectors.

It is important for sellers to realise the vast majority of us don't look to make money from these bikes simply to enjoy the process but at this buy in starter level cost we are now being asked to pay together with the cost of chroming, paint, spares etc we need to bear this is going to price us out of the market, then ask yourself who exactly is going to buy your bike when we are gone? Have a look at the bikes for sale and you will see far better machines for less, there is currently a Honda CB500X 2020, great bike to quote Trump, mature owner under 10k on the clock, an absolute belter up for sale at £3750! Time to get real I think and stop trying to squeeze the pips.

Her seat arrives and we are totally blown away with it, thank you Saddlecraft for your artist work which we highly recommend to those of you looking to recover a motorcycle seat!

The hand made tank has been an absolute pig of a job what with the "glued on" filler cap to the thick coat of bodge we had our work cut out for sure. That said a great local business was happy to help doing the weld work and of course our amazing polisher did not let a bit of bodge put him off, oh no, she is well on the way to being an absolute diamond, work in progress yes but you can start to see the tank coming out. We recently had the dents filled in with a degree of skill rarely on show today, we thank them very much for their work. Tank is now in the latter stages of polishing, truth be told we cannot wait to see it on the bike!

Here's a great find for all of you collectors of bikes who are constantly checking if the tax is out, even though it is free for most of us older bike guys it still needs to be applied for every year, the MOT's, insurance, yes I know it is a minefield and I guess we have all paid the fines but get a load of this new app, we love it!

Welcome to the the DVLA's "Vehicle Smart" app, an absolute game changer for the motorcycle collector who has a file full of V5's, yes I know so do we.

I hear you sceptics thinking we are being watched, you know your right of course we are but this is a really positive step forward from this lot that will help you get on top of your collection.

For a lifetime membership of £24.95 you can add up to 50 bikes or cars, the app allows you to limited but useful access of the DVLA information on the status of the bike, is it mot'd, tax'd etc, you can set auto reminders, you need to set the insurance yourself but when you do you get these as well, let's be fair you should never forget to tax, mot or to insure another vehicle again, happy days!

The app is very easy to use especially for those, like me, who are self professed "techno cripples".

The basic package is a bit mean at only 3 bikes and probably not enough for people like us especially when you will probably use it for all your vehicles not just your hobby ones, lifetime membership is better allowing up to 50 cars or bikes so more than enough for us amateurs and even some professionals. The package has a few extras on as well including free PNC stolen checks and reduced cost vehicle checks.

Available on your app store now, recommended in basic or lifetime form you will appreciate it!

What do 70's Hondas and Crypto Currency have in common?

People are starting to see them as a way of making a fast buck!

So we are certainly seeing more and more increases in 70's motorcycle prices which I suppose we expected, that said prices are not rising faster than anticipated. It is fair to say pretty much in line with our thoughts, interested people are getting more and more to the retirement age and ask themselves what they are going to do now, cars are both too big and too difficult to work on, you just end up lying under the stupid thing to fix it then leave it in the elements letting rust do it's thing. So bikes, well not such a problem as we can tuck them away at the back of the garage, a simple bike lift is costly, circa £550, but allows garage like facilities without crawling along the floor, bikes just fit the purpose and to boot are absolutely beautiful pieces of art.

So far so good and the supply of old bikes seems very plentiful, we see hundreds of them every day on popular auction sites, social media platforms, classic motorcycle shops and of course those live auctions that love to add 18% plus to the hammer price, buyer beware!

So are bikes the problem, well as it turns out no, there not, however we have been buying spares for some time now typically from auction sites and we cannot believe what people recently have been asking for parts, let me give you some examples, currently as I write this there is listed for sale a CB400/4 fuel filler cap, asking price is £78.97 yet at David Silvers you can buy the same one for £54.00, a new battery is listed at £77.75 yet again David Silvers is £47.94!

Now you may think I am splitting hairs but wait on as for me their taking the proverbial!

A set of carbs £1000, a tank that looks like the kids have been playing football with it at a penny off £100, an old rough rear wheel £155, used starter motor almost £75, dynamo cover at near £68 with a beaten up scratched one asking £25, 4 used inlet rubbers £36.99 and the list goes on, just remember here those inlet rubbers are best bought new and only cost £34.80 at Silvers and although the others may be original in this case then they are certainly going to be pretty hardened and I suggest the new would be a far better bet.

Am I being picky? Possibly and I guess I should be pleased these are available I hear you say, but when you can buy a complete CB400/4 engine for £595 currently available on 'you know where' these prices are best seem speculative, at worst they are taking the p*** of us hobby guys who are looking to put these bikes back to great condition, we all want to make a bit somewhere along the line I get that but not many of us renovators do this for profit, if this goes on we are at risk of monetising our hobby where people look to buy the bikes that we want to restore simply to strip them and sell them back to us as we need the parts, maybe they already are!

To be honest we all know that if you build a new car from spare parts bought at a dealer it would cost a fortune, let's not become like these greedy b***rds and keep this hobby an honest one.

Ours is a hobby for decent people, please don't treat us like cash cows available to finance your needs!

Still early days but the shape is all Honda

The paintwork for the now called "Rickman Honda CB500/4 Cafe Racer" arrives and we are delighted

Been a while since these were current!

Our newest acquisition ... Bruno!

Not at all bad for 47 years!

Project shots as we dig into this beauty

This engine should be just the ticket for the Cafe Racer with the look we are going for.

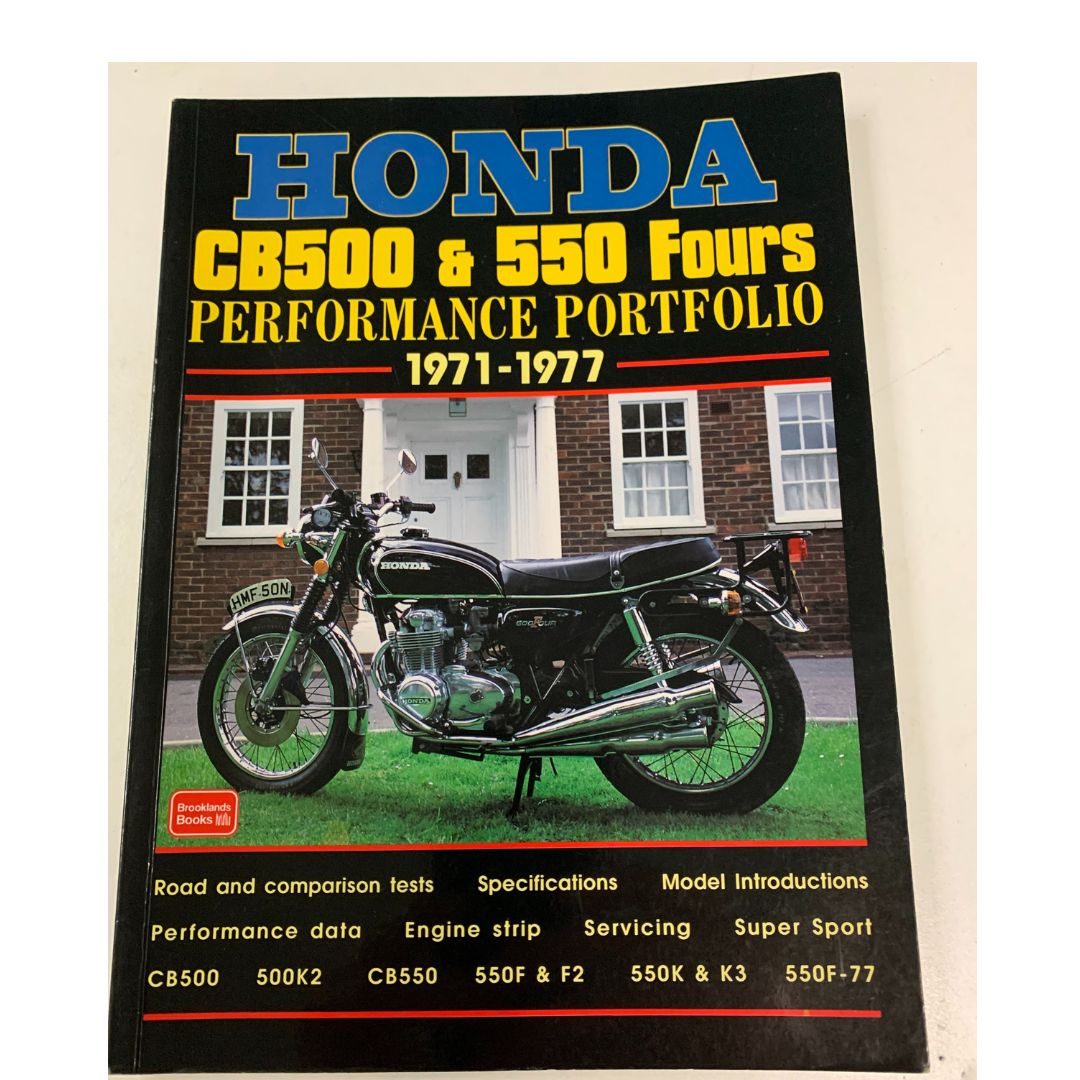

Many thanks to Brian for this amazing encyclopedia almost of the CB500/4

This publication covers an in depth analysis of the bikes in the various offerings. A really interesting engine rebuild section is daunting but available. One for the resource shelf!

Our new dials arrive and they look good!

The dials have arrived and on first inspection they look really good. Unlike previous ones we have bought these are on thick plastic or aluminium bases so replacements rather than stick on upgrades. We will see on the build if this is better but it would appear so. A good idea is to also buy new grommets, this supplier had them available so it was a no brainer.

30 seconds about zinc.

We thought we needed a good zinc plater but what are the parameters to build a good working relationship

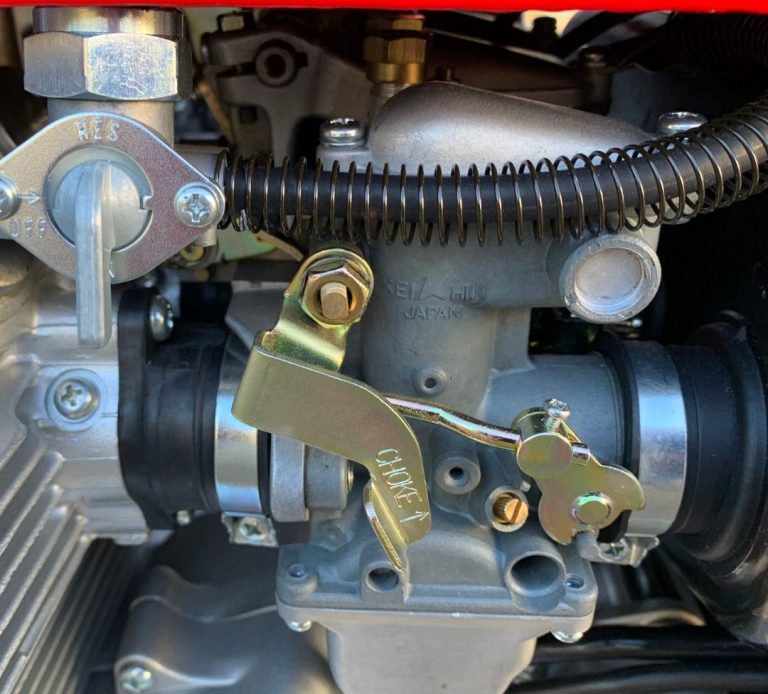

In this hobby finish is all important and to get that nut and bolt look you need zinc. For instance the choke levers are all yellow zinc which is a passivate, the bolts are a simple electro-deposited coating which as long as the parts are clean will look right. If your building a cafe racer the black options could be perfect again a passivation. The passivation process is a secondary process that can change the finish appearance and improve its durability, these include yellow/gold as shown on the choke, clear, chrome-free and black as shown on the fuel pipe protector. We have seen resistance from commercial operations to us bike builders as we bring in a bucket of rusty, oily and not to put too fine a point on it nasty products fully expecting them to magically wave a wand, a wand they have got, for very little money and return us a pristine set of product. We suggest you take a moment and think how best to approach these companies, remember there are others who follow us and will suffer the wrath of our ways. Getting the items vapour blasted (see suppliers) before you get to the platers is expensive but a really good way to show good faith, trust me they will be more likely to respond to your requests as it becomes a far easier task. A lot of zinc platers have blast facilities but we certainly think a bit of thought by us goes a long way here and builds a platform for us to use all in the years to come.

CB500/4's currently in the "to do" shed

From the left our Candy Garnet Brown, Bucchus Olive Green, Black and Candy Starlight Gold bikes

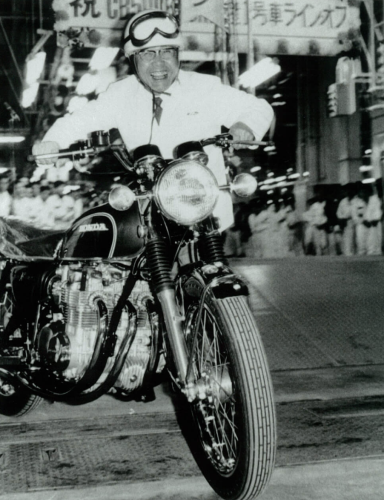

Our visit to David Silver's CB400/4 day was amazing!

We were blessed with perfect weather for the day which lifted the event even more, if that was possible, as 400/4's literally poured into the car park. The band played and the people mingled, we will post a full update later but for now we thank David Silver for his efforts to create such an amazing day.

How far is too far?

We start to ask ourselves the question what we really have to do when we start a project and what lengths do we need to go to to get what we want? Indeed what are the perameters of the job, are we creating a "concours" show bike never to be ridden, just showed? Are we creating a useable classic? Are we looking to sell on and if so what are our cost restrictions as to the project?

It's more difficult than you think to asses the level of rebuild we are going to achieve, obviously we want something as good as we can get, that is the hobby but to go 100% will cost more than you will ever recover and that does sting slightly. So you always end up with some sort of a compromise, if not you will end up having a full engine overhaul and top end seal rebuild, sometimes you cannot avoid that but not always, then you are never going to get the electrics back to new so it is a new full harness, then the chrome and trust me there is a world of financial pain where chrome is concerned and the list just keeps on going.

Now, let's get this right I am not saying going "all in" is a bad idea but I am saying you need deep pockets to achieve a concours example and you will need to accept a financial loss at the end of the build, if your looking to reward yourself for your trouble your onto a loser I am afraid.

But to fully appreciate the levels of restoration you can go to a full 100% nut and bolt rebuild is the only way, other than this you will have a job on all the time, new zinc here, new chrome there, and the bike will always be wanting.

The decision is yours but be fully aware of the outcome, it is better to agree in your mind what you are doing and maybe more importantly why? The journey will find its own path once you determine the stop your getting off at, or indeed the end of the line so to speak.

Whatever you decide we wish you well with your build, they are at times infuriating, at times exhilarating and always fun, just be sure you know what your letting yourself in for right up front, some people will ask you over your life for a commitment that they really have no intention of honouring, in this game you have no choice, maybe people who ruin others lives by their actions should also think about what they want before asking massive questions but maybe that's another topic for another day?

For me I feel to create as new as possible an example is the only real way to do justice to your passion, costly? Yes, difficult? Absolutely, worth it? You bet!

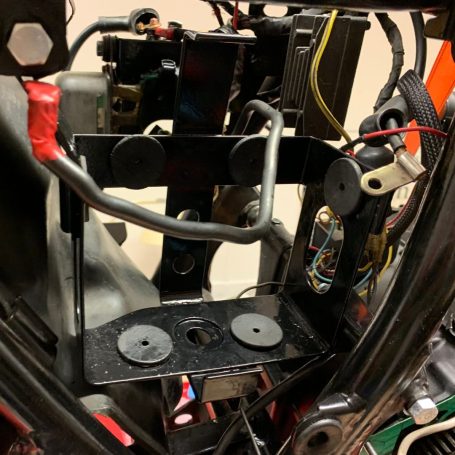

Esmerelda gets a new wiring harness

It is important to set a target when setting out on any project as they can run away with you if your not careful. That said we have always suggested Esmerelda would go full nut and bolt without actually saying the words, we can all understand that can we not! Well now we have acquired a brand new harness this takes us one step closer to this exciting project and, we hope, gets us over a major headache of any build, the electrics! We will keep you up to date as time passes but whatever happens she is going to be special!

Esmarelda gets a new coat

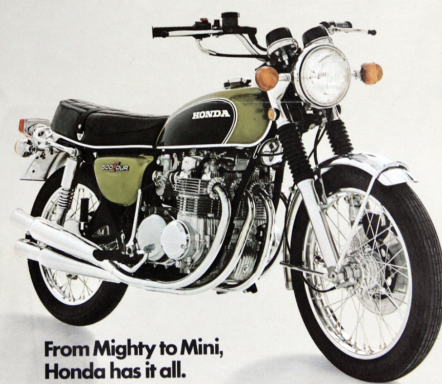

Our upcoming project 'Esmerelda' is named after the latin word esmeraldus meaning 'bright green precious stone' and of course in Spanish means Emerald, which we hope she will become in time. We found her in the Isle of Wight and we did say at the time we fancied going all out on her, well the tank and side panels are nearing completion and I think you will agree, Bucchus Olive Green is an amazing start on her journey of what looks more and more a nut and bolt job! Together with Michaels skill to apply the pinstripes in paint, a better way we feel, we have been able to source a reproduction Mole unit for the chrome effect along the base, we were lucky as they are very rare so we grabbed it when it became available.

Our thanks to Michael at North East Custom Coatings for his work on this project and RS Bike Paint Ltd for the supply of the Bucchus Olive Green we needed.

Meet Gavin ... buyer beware!

Gavin is a CB500/4 K1 with high miles on the clock, always a worry. It came to us as a good solid bike, and indeed he is. That said he has been subject to neglect as so many bikes are today. The tank and sidepanels were so grubby our clay bars were sticking even with a lube applied and we needed to revert to sterner stuff but even then after an appraisal at the paint shop it is off with the old and he is going Candy Garnet Brown! The frame is covered in areas of rust, powder coating is a necessity here. The engine was anodising and will take some hours of polishing to make good again and with our friends RS Paintwork we will be able to repaint him in exactly the correct colours before it goes back into the frame. The chromework was better than expected with a decent front end and rear mudguard however the pipes were shot but we have a spare set thankfully so these will be very useful. The wheels will be our first time to rebuild with new rims and spokes kindly supplied by David Silver Spares.

Engine wise we are not sure yet as he is only running on numbers 1 and 4 suggesting a dead left hand coil but we tend to replace coils on our rebuilds nowerdays so this may well rectify itself however one area of concern is what is this masking as the seller knew of the issue removing the coils to 2 and 3 and there may be a reason, time will tell, remember it was sold to us as a runner, yes, on 2 cylinders thanks very much, is honesty so difficult nowerdays?

Other than this he will be treated to the normal Four Bores upgrades including the clocks and brakes overhauled then though I believe we will have a really good English CB500/4 which will turn a few heads as time goes by.

New rubber for our CB400/4

We plump for Bridgestone's latest offering, the BT46

Bridgestone certainly make great tyes, I run BT45's on the CB500's but the latest BT46 boasts a "Silica Rich Compound" which, they say, offers better grip in the early stages of a ride, really good to hear as we all know our grip, or lack of it, in the wet but how many of us adjust grip capability when we just pull away, especially on a cold day?

Age is only a number, these are over 50

These clocks, although decent and in working order needed new dials and a lick of paint. See how we managed to open and close them with a handy home made jig which made life a lot easier

Any difficult job is really just a whole lot of easy jobs put together!

"Esmerelda's" engine was left to its own devices without carbs on to in any way try to protect the bores for 20+ years, which is sadly more often than not the fate of many a superb CB500/4 K1. This one we found in the Isle of Wight and its engine is currently undergoing a full rebuild for the next project where we take on "Esmerelda" with warts and all!.

Vanquish our CB400/4 F1

Our first project was this really beautiful Honda now nearing completion, the BT46's are for her. Left to it's own devices for many years it was first bought by Phil some 10 years ago where he started to think how best to restore her, check out the latest photo's as to where she is today. We are looking to clear coat the tank and sidepanels over the logo's before we apply the finishing touches.

One for the future a CB400/4 F2

The better one of our stock ready for rebuild is this Parakeet Yellow beauty, well I say beauty but in reality she has suffered the indignity of having her frame painted red which does her no favours! That said underneath she is a super base bike to rebuild, the F2 was given a neat new look including stripes on the tank, original "go faster" stripes? Perhaps. The frame was changed to accept the rear footrests to be on a loop from the main body. New colours included the aforementioned Parakeet Yellow and Candy Antares Red.

We welcome "Esmerelda" feeling a bit under the weather!

We love these bikes, to us they are a thing of beauty, well most of the time! This one is described in more detail on the projects page but she is going to be a challenge.

Were off to the vapour blasters!

These look pretty grubby but our friend Jill knows just what they need! There going to a 'new to us' Zinc plater business near Newcastle, if good we will publish their information for you in due course.

Before ...

And after ... what a difference, now the platers beckons!

"Esmerelda" a CB500/4 K1

Time takes it's toll

Hens Teeth

You really don't get much more rare than this find, I know, it's a box, but no ordinary box as it contains an original set of pipes for a Honda 400/4 F1 kindly supplied to us by David Silver Parts. We are also very fortunate to own a similar set of pipes OEM brand new, again in the box, set of tulip pipes for a CB500/4 K1, amazing find!

A tank needs to be right

We are blessed today having a veritable industry of business' set up to pander after our every need and here is a gorgeous tank and side panels for the F1 project in Varnish Blue, pretty as a picture.

This tank is now ready and will be fitted soon, look forward to the images to follow... We have just also awarded a job for our next project, a tank and side panels to one of our best local 'artists' otherwise known as 'North East Custom Coatings' to create a Bucchus Olive Green tank and side panels, these are now on the Gallery and look tremendous, see gallery.

Another Clocks job for our next project

Believe it or not these are pretty good, yes obviously the inner dials are shot but they can be replaced, we will publish our jig for ensuring the dials drop perfectly into place at a later date, the outer casings are just in need of a good rub down and a couple of coats of paint, the bases are really good, a nice set of clocks off a CB500/4 K1 that soon will be pride of place on the CB500/4 project coming along shortly. We have found a new dial supplier, this order has been placed with them, we have a few to do but as a first try we will just go for this set, if we like them we will look to add them to our suppliers page, fingers crossed.

New stock arrives

These bikes offer us a wealth of potential in parts, one of them is destined to go full rebuild, maybe two, can you spot Esmerelda?

We look at Vapour Blasting / Honing, amazing yes but you do need to understand the jobs that are wise after the parts come back.

Vapour Blasting, what a find, a very gentle way of cleaning parts to a level that on many occasions is perfect for us renovation hobbyists. So what is vapour blasting? It is a process that uses an abrasive media, glass beads, suspended in water, if you want to see what that looks like see the image below, that's the stuff, applied with a pressurised blasting technique to remove dirt / light rust (and more) while simultaneously cleaning and prepping a surface. Now the important part is abrasive, the process uses the finest of particles, abrasive media, which is suspended in water and we need to understand this can cause us problems in certain instances. Materials that are suitable are wide ranging, things like aluminium, stainless steel, brass, copper, mild steel, rubber, and plastics can all be candidates for this cleaning method.

With this in mind when we send parts into the basters it is good to dismantle parts to the absolute max, nuts and bolts separated, parts dismantled as far as possible so this abrasive medium does not stay in the parts as best as possible. As you can see with the images our footpegs came out really good but look as what is left underneath the rubber, this is because we left the rubber in place, mistake, we should have dismantled them as far as they go.

Sometimes we cannot help this residue for example a thread will gather the medium around the nut if left on when processed, the threads already are areas that need to be cleaned by running a nut over them even if done without the nuts left on, and believe me when I say the nuts can be tight, gritty and sometimes very difficult to screw back on, I find turning in and out slowly working further on, small turns and gently until you are all the way in, take your time. When doing parts with small screws it is more obvious, you will need to be very careful putting the screws back in to threads as they probably will be gummed up with the medium, this is easily resolved once you know what your dealing with, use a blast or two of wd40 to take the medium out things if needed.

We had a set of carbs blasted with fabulous results, it was our first time and the screws just did not want to go back in at all, the threads on the inside were absolutely impossible to screw straight in, we were at a loss until we clicked, in out in out and patience and guess what, they freed off easily, it is worth noting that once done there is no need to do again.

Now you can understand why engines need to be fully striped before blasting, wheels need the bearings out, trust me the bearings would be toast if they were left in.

Vapour Blasting, or honing is an absolutely fantastic way we can gently return parts to their original look, especially rubber and plastic, alloy casings and heads, unreal once you realise what you have to do once finished.

We are starting on a nut and bolt restoration of a pretty poor in all honesty CB500/4 K1 so we are using this process for the engine bolts and the end result is truly superb, we needed to really take time to clean the threads as discussed and of course wire wheel the heads before zinc plating, a long and laborious job but the end result makes it all worthwhile.

So, vapour blasting, what do we think? No question it is a gamechanger, just be aware of what your working with, understand how you need to finish the parts, what you can and what you cannot use with this process and your away, the people we use are also extremely knowledgeable, do great work and are really nice to boot! They are only to happy to help us through the method, we suggest use this invaluable source of knowledge in this case.

It's mechanics Jim but not as we know it!

We get to grips with a heavy clutch, the old CB500/4 K1 had a couple of issues, read how we got on here.

Get in touch

We have lots of experience now working on these bikes, if you are a beginner and just need some help or perhaps you are looking to get into the hobby please feel free to get in touch, we would be only to happy to help as and where we can

David Silver holds an open day in celebration of 50 years of the Honda CB400/4

Open Day plus 50 Years Celebration of the iconic Honda CB400F Four - Saturday 28th September 2024

Honda Open Day with LIVE 1970s Rock Music and Best-in-Class Contest Celebrating 50 Years of the iconic Honda CB400F Four.

Having first gone on sale in 1975 the CB400F soon became a favourite amongst British bikers and has remained a much-loved classic for almost 50-years!

The FREE admission event is open to all motorcycle enthusiasts and for those with a1970s Honda CB400F a contest will be held to find the ‘Best-in-Class’ in 6 different categories.

The special Open Day will featurethe following…

• Unique display ofan extensive array of 1970s CB400F’s

• Judging &Awards Ceremony with 6 different ‘Best-in-Class’ CB400F awards.

• LIVE 1960s/70s/80s rock-music band.

• Honda CB400F HistoryQuiz’ – Win a £100.00 Honda Parts Voucher!

• CB400F Used Parts Auto jumble (plots available, see below)

• FREE entry to the event with FREE car & motorcycle parking.

• FREE admission to museum with over 200 period Honda motorcycles on display.

• Hot/Cold food refreshments plus drinks bar.

• Honda new parts& used bike sales counter open.

• Visitor facilities including disabled access to the museum.

Three Bores of the Four Bores Team

The Founders

Philip

Founder

Phil is in charge of visuals, he passes finishes, ensures things look as they should and generally keeps us all on our toes. A master when things are difficult he is the go to man when things are stuck, as they more often than not are of course!

Kev

Founder

Kev is our technical guru, electrics being his speciality but all things really, if it doesn't work don't worry, Kev will work it out in, well sometimes days but who's counting!

Ian

Founder

Haynes manual expert (relative) and tea maker extraordinaire Ian is a safe pair of hands always happy to take on any job with an open mind. An eternal optimist he loves to see progress as the bike comes together.

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.